Ever wondered what it’s like to go into a “clean room”? A couple weeks ago a group of students from the Center for Sustainable Nanotechnology (CSN) got to find out during a tour at the Minnesota Nano Center.

Earlier this month, eight undergraduate summer research students who are working at CSN labs around the country came to the University of Minnesota for a 1.5-day mini-conference. As part of the meeting, we had the opportunity to visit the Minnesota Nano Center (MNC), a “state-of-the-art facility for interdisciplinary research in nanoscience and applied nanotechnology.”1

What does that mean? At the MNC, researchers study new ways to make sensors, circuits, and other devices smaller and unbelievably smaller. You might have seen an old-fashioned circuit board like this at some point, with components like resistors and capacitors that are easily visible to the naked eye:

This technology was the basis for everything from radios to early computers, but the size of the components ultimately limits what they can do. Jim Marti, Senior Scientist and Outreach Coordinator at the MNC (and our generous tour guide) estimated that it would take a traditional circuit board the size of a city block to provide the computing power of a modern cell phone!

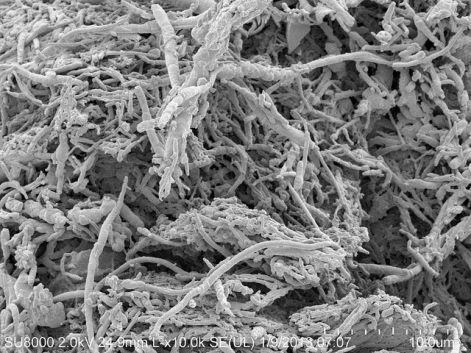

That’s where nanotechnology comes in. Research at the Minnesota Nano Center contributes to new technologies being able to shrink more and more so that millions of components can fit into your pocket. But you know what else is a million times smaller than those old-fashioned circuits?

Dust.

Even though we can’t see it, the air we walk through and breathe every day is full of tiny dust particles, and although they don’t do us any harm (though they might make some of us sneeze when we’re cleaning), they can wreak havoc on research or manufacturing of technology that is on the same scale. (As an analogy, think about the damage a one-meter boulder could do to a three-meter-long car…)

A typical urban outdoor street has about 1,000,000 dust particles at least half a millimeter in size per cubic foot of air.2 A Class 100 clean room like the one at the MNC is so clean that it has no more than 100 particles per cubic foot!

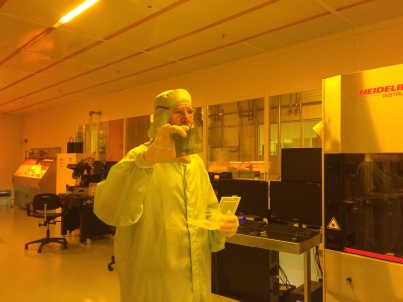

In order to keep the clean room clean, anyone who wants to go inside has to wear a protective suit to keep the miasma of dust on our clothes from interfering with the research. That includes visitors like us as well as researchers who work there every day.

The first pieces of our clean room outfits were a hair net like you might wear when preparing food at a restaurant, and disposable booties that you might have seen at a hospital or even a real estate open house. But that was just the beginning!

Next came a full Tyvek coverall, a hood to go over the hairnet, boots to go over the disposable booties, and gloves, and we were ready to go! There was even a sticky mat on the floor in the doorway to catch any last particles that might be clinging to the bottom of our boots from the floor of the dressing room.

Once in the clean room, we got to see an array of cool instruments, including machines that deposit atom-thin layers of different materials on silicon wafers, lasers that etch patterns into those thin layers, and microscopes that can visualize structures smaller than the wavelength of visible light! One area had yellow lighting because special blue lights are used for a type of lithography – this works the same way that red lights are used in a traditional darkroom to prevent premature exposure of photographic film. (Check out this blog post for more on photolithography.)

The type of nanofabrication research they do at the Minnesota Nano Center is pretty different from our work in the Center for Sustainable Nanotechnology — CSN researchers are more likely to make nanoparticles or observe how nanomaterials interact with cells as opposed to making nanoscale circuits or sensors. It was fascinating to get a glimpse into this other facet of nanoscale research. And (unless you work at the MNC) it’s not every day you get to go into a room with air that is 1,000 times cleaner than what we breathe outside every day!

EDUCATIONAL RESOURCES

- NISEnet video: What happens in a nano lab? (ages 4+)

- NISEnet video and activity: Exploring tools: Dress up like a nanoscientist (ages 4+)

- Journal of Chemical Education article “Hands-on Classroom Photolithography Laboratory Module To Explore Nanotechnology” by Stelick et al. (age 12+, may require subscription)

REFERENCES

- Minnesota Nano Center website: www.nfc.umn.edu/

- Clean Air Technology, Inc. website: www.cleanairtechnology.com/cleanroom-classifications-class.php