I like bicycles. As a kid, bikes were part of carefree, blue-skied summer days endlessly circling the neighborhood cul-de-sac with friends until the street lamps turned on and our mothers called us inside for dinner. These days I ride bikes to get to and from work, for exercise, for fun, for grad school stress relief, and as a competitive outlet on a racing team. Bikes are a big part of my life and I like sharing them with others. Last summer I taught Mimi Hang, fellow CSN researcher and blog author, how to ride a bike. After 5 minutes of wobbly progression down the bike path, Mimi bubbled over with excitement and exclaimed: “I can feel the wind on my face!” Maybe it’s bold to say this, but I like to think that everyone can identify with bikes in some form.

This is a blog about sustainable nanotechnology, so what’s the connection to bikes? In one of those peculiar but common intersections of life passions, it turns out there is a lot of chemistry involved in riding, designing, and manufacturing bikes. In the past decade the cycling industry has caught on to the unique properties of nanomaterials, and in the next two blog posts I’m going to tell you about a couple of those nanomaterials currently being used in the industry along with some pseudoscience marketing (uh-oh!). Buckle your helmet, it’s going to be a wild ride.

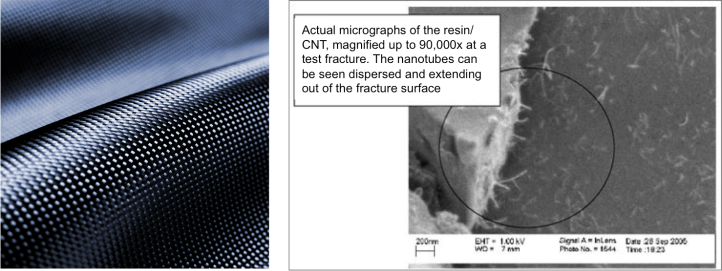

The 2006 edition of the annual Tour de France, the most famous bicycle race in the world, was a win for Floyd Landis* and for the carbon nanotubes mixed into his bike frame.1 Carbon nanotubes (the same substance from our recent posts about flame retardants and water purification) are a form of hexagonally arranged carbon atoms wrapped into a cylinder. They look a bit like chicken wire rolled into a tube, where the wall of the tube is exactly one carbon atom thick (this dimension is why they are called nanotubes). As far as I can tell, Floyd Landis’ bike was the first example of a nanomaterial being used in a commercial bicycle design.

Carbon nanotubes (CNTs) came into the scientific limelight in the 1990s because of their unique structure and associated properties: for example, they can conduct 5 times more electricity and 15 times more heat than copper. BMC, the Swiss company that manufactured Landis’ bike in collaboration with Easton Sports of the USA,2 took note of CNTs’ unmatched strength and stiffness relative to their weight: CNTs are 200 times stronger3 and 5 times more elastic (i.e. less brittle) than steel with about half the density of aluminum.4 These impressive properties of carbon nanotubes can all be credited to the very particular nanoscale arrangement of carbon atoms in the material and are good reasons for using them in a bike frame.

BMC racing bikes are made out of carbon fiber, a material consisting of long 5-10 micrometer thick fibers woven into flexible sheets (for scale, a strand of hair is ~100 micrometers thick). These sheets are layered and molded into the shape of a bike frame. A sticky resin (think of glue) is then used to hold the layers together. Carbon fiber is considered a composite material because it combines two or more materials with different physical or chemical properties to create a new material with distinctive characteristics. In the case of a bike, the flexible but strong woven carbon fibers are given structure by the brittle resin used to bind them together. Ultimately this creates a bike frame that is not just shaped like a bike frame but is also strong in all the necessary places.

Working with composite materials to get a product with desirable properties takes a lot of intentional engineering. In this case, BMC was able to decrease weight and increase strength even more by replacing some of the carbon fiber resin with stiff, robust, and lighter carbon nanotubes. Landis’ bike frame (without wheels, handlebars, saddle, or gears) weighed only 2.11 pounds5 (roughly the same as two full pint glasses) but was strong enough to survive being ridden all 2,272 miles (almost 90 hours) of the Tour de France!6

Though BMC’s CNT bike frame was commercially available in 2006, to my knowledge, BMC does not make bike frames with CNTs today and only three other boutique brands (Spanish-based BH Bicycles7 and Italian-based companies Pinarello8 and Dolan Tuono9) have consistently included CNTs in their frames since 2006. With the exception of a single design from Cannondale in 2013,10 none of the major bicycle manufacturers—think Trek, Specialized, or Giant—have advertised working with CNTs. Eeeeep!

If CNTs have such great properties, why haven’t they taken off in the bicycle manufacturing world?! Cost is a big factor: it wasn’t until 2007 that an economical way of making large amounts of pure CNTs was demonstrated in a lab.11 And even with that method, these bikes have price tags starting at $7,000 today!7-10 Although a lot of pure CNTs can now be produced, they are difficult to work with because they tend to bundle together when mixed with other materials like resin. Imagine steel cables in concrete that are wadded up in a ball versus lined up in rows and columns – like steel cables, CNTs can’t add much strength if they aren’t properly oriented.2

Despite all that, $7,000 might be a reasonable price to pay for a championship competition bike. Perhaps a bigger deterrent for mainstream bicycle manufacturers is the 15-pound minimum weight limit on complete race bikes (including frame, wheels, gears, saddle, and handlebars) enforced by the UCI, the international governing body of cycling. The minimum weight rule was first introduced in 2000 in an effort to ensure rider safety during the rapid adoption of lightweight carbon fiber-based equipment. Recently some teams have had to add lead weights to bikes to reach the minimum limit, causing the UCI technical manager to reconsider the regulation.12 Only time will tell if carbon nanotubes will win another Tour de France.

So are carbon nanotubes the end of an underwhelming story about nanomaterials in bikes? NOPE. I’ll tell you more in part 2 of this series later this week! To whet your appetite, check out this video of a puncture resistant tire:

*Floyd Landis was later stripped of his Tour de France win after testing positive for performance enhancing drugs. But his bike still travelled all those miles so I’m letting it keep the credit in this blog post.

EDUCATIONAL RESOURCES

- Nanoscale Informal Science Education Network: World of Carbon Nanotubes (ages 4+)

- Materials Research Science and Engineering Center: How Small are Nanotubes? (middle school)

- National Science Teachers Association: The Structures and Properties of Carbon WebNews Digest

- Kanellos, Michael. Carbon Nanotubes Enter Tour De France. CNET. 10 July 2006. Retrieved from http://www.cnet.com/news/carbon-nanotubes-enter-tour-de-france/

- Zyvex Corporation. Easton Sports, Inc teams with Zyvex Corporation to apply carbon nanotube technology to bicycle products [press release]. PRNewswire. 1 Sept 2004. Retrieved from http://www.prnewswire.com/news-releases/easton-sports-inc-teams-with-zyvex-corporation-to-apply-carbon-nanotube-technology-to-bicycle-products-71830587.html

- Yu, M-F., Lourie, O., Dyer, M., Moloni, K., Kelly, T., Ruoff, R. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science. 2000, 287 (5453), 637-640. doi: 10.1126/science.287.5453.637

- Sinnot, S., Andrews, R. Carbon Nanotubes: Synthesis, properties, and applications. Critical Reviews in Solid State and Materials Sciences. 2001, 26 (3), 145-249. doi: 10.1080/20014091104189

- Pestes, R. PEZ-Clusive Test: BMC SLC01. PEZ Cycling News. 23 March 2006. Retrieved from http://www.pezcyclingnews.com/tech-n-spec/pez-reviews-bmc-slc01/

- Churchill, G. 2006 Tour de France Course Profile. 28 Oct 2005. Retrieved from http://www.roadcycling.com/news-results/2006-tour-de-france-course-profile

- “BH G4 Red” Road Bike Action Magazine. 14 July 2008. Retrieved from http://roadbikeaction.com/bike-tests/bh-g4-red

- Cicli Pinarello. Torayca 65HM1K with Nanoalloy technology. Retrieved from http://www.pinarello.com/en/technology/road-asymmetric

- Smith, P. Review: Dolan Tuono. Cycling News. 17 March 2008. Retrieved from http://www.cyclingnews.com/reviews/dolan-tuono/

- Stickland, B. Flickinger, L., Sherry, J., Furia, E., Ford, B., Liu, G., Rojek, T., Weinberger, H., Koch, R., Yozell, M., Zuckergood, S. Buyer’s Guide: Road Bikes. Bicycling. 8 March 2013. Retrieved from http://www.bicycling.com/bikes-and-gear-features/buyers-guide-road-bikes?slide=4

- Kumar, M., Ando, Y. Carbon nanotubes from camphor: an environmentally friendly nanotechnology. Journal of Physics: Conference Series: International Conference on Nanoscience and Technology. 2007. 61: 643-646. doi: 10.1088/1742-6596/61/1/129

- Robertshaw, H. UCI considering scrapping 6.8kg bike weight limit. Cycling Weekly. 14 Dec 2015. Retrieved from http://www.cyclingweekly.co.uk/news/latest-news/uci-considering-scrapping-6-8kg-bike-weight-limit-203804

[…] Want to know more about carbon nanotubes? Check out our posts on plastic bags, flame retardants, water purification, and bicycle tires. […]

[…] original en inglés por Margaret Robinson Traducido por […]

I think the admin of this web page is truly working hard in support of his website, because here every data is

quality based stuff.

[…] my previous post, I told you about the impressive properties of carbon nanotubes (CNTs) and how they can increase […]