“You’ve gotta give it a taste to know!” answered the long-haired, cowboy shirt-wearing distiller dude at Madison, Wisconsin’s Old Sugar Distillery. He was responding to my incessant questions about how long their liquors take to age. His answer was interesting, but I wanted numbers! After some more pointed questions, he told me that most of their liquors take around 5 months to age properly in their smaller-than-usual 5-gallon barrels—”about a month per gallon,” the distiller/bartender informed me. With those numbers in hand, I knew I had the key to connecting my occasional nighttime interest, liquor, to my constant daytime interest, nanotechnology. Stay with me…

In order for Kentucky Whiskey to be called “straight bourbon,” it must be aged for a minimum of two years. This is way longer than the five months of aging that happens on the corner of Main and Brearly in Madison. According to lots of new startup craft distilleries like the Old Sugar Distillery, their small barrels are the key reason they can churn out their liquors so much more quickly than the big distilleries, who typically use large 53-gallon barrels.

Smaller barrels = quicker liquor?

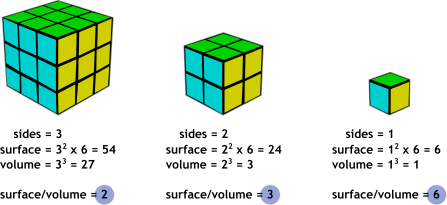

As a liquor sits in its barrel, the flavor changes through two slow processes. One change is the result of flavorful and colorful chemicals slowly migrating from the wood into the liquor. The other change occurs as the chemicals in the liquor slowly change their atomic structure by reacting with chemicals in the wood as well as with oxygen from the air—creating brand new chemicals and brand new flavors. Barrel size primarily affects the rate of the first process. The smaller size allows for more contact between the inner barrel surface and the liquor, which allows the flavor chemicals to hop into the liquor much more quickly. There is more liquor/barrel intermingling because as objects get smaller, they have more surface area than they do volume. This is shown below for external surface area of cubes, but the same applies for internal surface area of hollow objects like barrels.

So even though the 53-gallon and 5-gallon barrels are made of the same stuff, their interactions with other things change as a function of their size. The smaller barrel is unique because it allows for more rapid aging of liquors (though some argue the liquors aren’t quite as nice as those aged traditionally).

Size Matters in Liquor and Energy Production

Much next generation solar technology takes advantage of a similar phenomenon. Most solar cells currently on the market are made of silicon. Dark crystals of this substance absorb energy from sunlight and inject electrons into an electric circuit—thus creating the electricity we know so well.

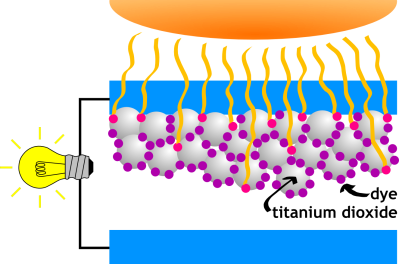

A new type of solar cell in development is made of much cheaper chemicals, like titanium dioxide. The only problem with titanium dioxide is it is white, so doesn’t absorb any visible light. White paint and other white things you buy likely contain titanium dioxide, because it’s so good at making things white!

A solar cell that doesn’t absorb light would be useless. To get around this, researchers put a thin coating of a vibrantly colored chemical on the titanium dioxide surface. This colored “dye” then absorbs the light, which causes an electron to be injected into the titanium dioxide and on into the electrical circuit. This is known as a “dye-sensitized solar cell.”

However, just like large barrels take a long time to “inject” their delicious chemicals into liquor, a large chunk of titanium dioxide coated with a dye would generate electricity really slowly in part because only the dye-coated surface of the titanium dioxide chunk can absorb energy from the sun.1 The answer to this problems is to create more surface area for the titanium dioxide and dye to intermingle. Just like the distillers use smaller barrels, scientists just use smaller chunks of titanium dioxide to create more surface area.

Thus enter our good nanoparticle friends! They can be made in such small sizes (1 billionth of a meter!) that they are almost all surface! Coat the surface of titanium dioxide nanoparticles with dye molecules and you have the key ingredients for a reasonably efficient solar cell. There is so much dye-coated surface that they collect way more light energy from the sun than they would if they weren’t nano-structured.

Nano-liquor?

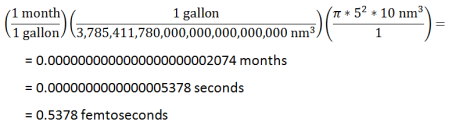

It works well for solar technology, so what about nanotechnology in liquor aging? Instead of a big 53-gallon or smaller 5-gallon barrel, what if distilleries used a nano-sized barrel? How quickly could you age the liquor inside a barrel that is 10 nanometers tall and 10 nanometers in diameter? What I’m about to do is a dramatic oversimplification that might upset many distillers and scientists alike. With that warning aside, I can say that a barrel that size would age the liquor inside it in approximately one half of a femtosecond.

That is SUPER fast! In 3000 femtoseconds, light travels just one meter! But, as I said before, it’s definitely not that simple. When you get down into nano-sizes, things just get weird, and I’ll leave the weirdness for another post.

All crazy speculation aside, there is way more science at work in both liquor aging and solar cell technology than just surface area. For that reason and because I need to get to the Old Sugar Distillery to pester the distiller with more questions while he’s there, I’m calling this post complete.

References and Further Reading:

Science of the Silicon Solar Cell (lots of cool animations!)

Craft of Whiskey Distilling (especially Chapter 4)

Whiskey Startups are Rolling Out a Small Barrel Sooner

Development of Titanium Dioxide Nanoparticle Solar Cells

Nanocrystalline Titanium Oxide Electrodes for Photovoltaic Applications (subscription required)

Footnote:

1 – A solar cell made of a big chunk of titanium dioxide would work poorly for a number of other reasons too, not just the surface area reason discussed here.

Sides 2// (Volume) 2x2x2=8, not “3”

Yep, looks like there’s a typo in the third figure! But the surface/volume ratio is still correct (24/8=3).

An excellent interactive from MIT technology review about next generation solar technology:

http://www.technologyreview.com/featuredstory/515646/how-advanced-solar-cells-work/

Great post. It’s nice to see science concepts in every day life context. Now I wonder, would a chocolate chip cookie flavor improve with by using smaller chocolate chips?

Excellent question! There’s only one way to find out really! But the chocolate should melt in your mouth more quickly at least. Feel free to send the results of the experiment my way.

Smaller chocolate chips wouldn’t enhance the chocolaty flavor as you would actually have less surface area of chocolate exposed to your taste buds. It would melt faster however because of the larger surface are to volume ratio. Now, expanding on that idea, you could make really thin chocolate chips that have the same volume as a conventional chip. By using these thin ones, most of the chip volume would be at the surface and in contact with your taste buds, and you would (or should?) get a stronger chocolate taste! They great chocolate flavor wouldn’t last as long though.

Another curiosity on that, why barrels? Why don’t they just use long wooden slats and make boxes? Sealing or mobility issues maybe?

Perhaps we are misunderstanding eachother, but comparing two batches of chocolate chips of equal mass but one batch is made of smaller chips… the batch with smaller chips would have a greater surface area and therefore have greater exposure to your taste buds. Regardless of the shape. I think thin chocolate chips are a great idea! I just bought some ice cream with thin chips in it and it is awesome! I do know that in low-fat chocolate shakes manufacturers are using smaller and smaller little beads of cocoa in order to get the same chocolate taste with less fat-containing chocolate.

Amazing question about barrels!! I had never even thought about that. My hunch is that this is just a historical remnant… there’s no reason for it, but people think liquor has to be aged in barrels… so perhaps it wouldn’t sell as well if it were being aged in wooden boxes??? You are probably right about sealing though. I know that barrels seal due to expansion of the wood upon exposure to the liquor. Perhaps it would be difficult to get the same effect in a cube? I’ll have to stop by the distillery again to pester the distiller. Hopefully I’ll do that soon, and will report back.