Have you ever wanted to have super-human vision? What would you do if you could record and play back video right in your contact lens? This might sound like science fiction but smart contact lens technology already exists that can do these amazing things and even more, such as medical sensing. (Figure 1). One of the things that makes the exponential growth of wearable electronics possible is the unique physical and chemical characteristics of a material in pencil lead: graphene.

Graphene is an ultra-thin sheet of carbon, a superb conductor and is 200 times stronger than steel while being incredibly flexible. (You can read more about graphene in this blog post.) Chemically, graphene is a single layer of atoms from the multi-layered structure of graphite, which is what makes up pencil lead.

Historically, people believed that graphene would be too difficult to make. In 1946, Canadian physicist Philip Russel Wallace, who was interested in studying graphite, “invented” a 2-D analog called graphene to help him theorize about properties of graphite. He argued that graphene had similar properties to graphite, but other scientists assumed he had made it up and it couldn’t exist in the real world.

It was not until 2004, when physicists Andre Geim and Konstantin Novoselove removed some flakes from a lump of bulk graphite with sticky tape during a “Friday night experiment,” that Wallace was proved correct. Geim and Novoselove successfully created flakes that were just one atom thick, showing that it was possible to isolate one layer of graphene, Wallace’s “made up” analog to graphite. Since everyone assumed that one-atom thick sheets could not be stable due to thermal fluctuation (like ice loses its crystal structure above 0 °C or 32°F), Geim and Novoselove’s initial findings were rejected twice for publication. Eventually, their paper was published in the journal Science,3 which sparked research in graphene internationally. Six years after their groundbreaking isolation of graphene, Geim and Novoselove were awarded the 2010 Nobel Prize in physics.

Graphene is ultra-light yet is 200 times sronger than steel; in fact, graphene is the strongest material ever measured.4 Despite its extraordinary strength, it is extremely light at 0.77 mg/m2 (The same area of paper is roughly 100 times heavier) and incredibly flexible. Graphene’s electronic properties are also extremely useful; it is a superb conductor. Jesus de La Fuente, the CEO of Graphenea, writes, “In terms of how far along we are to understanding the true properties of graphene, this is just the tip of iceberg.”

Because of its range of useful properties, graphene is an important component in smart contact lenses. One concern about smart contacts is that the continuous exposure to electromagnetic (EM) waves to our eyes when wearing smart contacts could lead to risk of low-temperature burn or dehydration. Typical materials and techniques used for electromagnetic (EM) shielding rely on metals, which add cost and weight (the last thing you want is heavy contact lenses!) But due to graphene’s outstanding electrical properties, gas-impermeability, optical transmittance, mechanical flexibility, and environmental stability, a group of researchers in Korea believe that graphene is a suitable material to add to contact lenses to shield the wearer’s eye from the continuous exposure to EM waves and protect them from dehydration.1

In their 2017 article, Lee et al. point out that EM waves pass through normal contact lenses and are directly absorbed by your eyes, which can potentially cause thermal damage that could lead to cataracts. Their study found that once the contact lens is coated with graphene, the EM waves are partially absorbed by the graphene layer, which would protect your eyes from the EM energy.

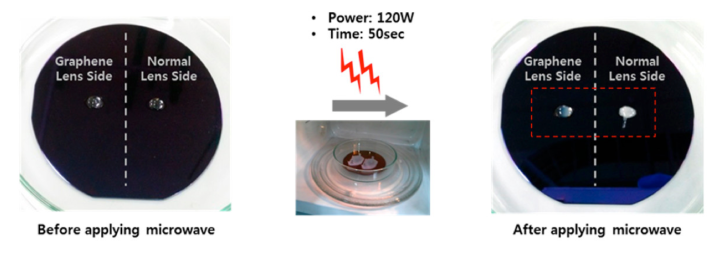

One ingenious way the scientists tested the protective properties of graphene was using eggs! They conducted an experiment in which they exposed an egg white sample to the irradiation of a high power EM wave in a microwave oven (whose wavelength is in the same range similar to 4G LTE and Bluetooth, but much more powerful). The egg underneath a normal contact lens was damaged, but the egg protected under the graphene-coated contact lens was barely damaged because the graphene absorbs EM energy and dissipates it as heat. (Of course, if this technology is to be used for people, researchers will have to figure out what to do about that heat, even if it is on the outside of the lens!) They also showed that graphene-coated contact lenses hold more water than traditional contact lenses, allowing your eyes to stay well-hydrated.

Although graphene coating on contact lenses was shown to facilitate hydration, it also reduces the oxygen permeation. Since blood carries oxygen, more blood means more oxygen, so this can lead to a problem called neovascularization, which is when the eye grows extra blood vessels to transport more blood as a response to oxygen deprivation of the eye. This doesn’t mean we can’t use graphene for contact lenses, though. The concern could be addressed by using graphene with nano-scale pores (holes) designed to control water vaporization. The pores in the graphene would then allow for oxygen to transport through the contact to reach the eye.

Smart contact lenses are not yet readily available to the public, but with the tremendous efforts of scientists and companies, we may be able to look forward to recording videos, having clearer vision, or monitoring our health just by wearing contacts. And if methods for scale-up and continuous production of graphene are developed, this nanomaterial has potential as a component to be incorporated into smart contact lenses to protect our eyes from EM waves and dehydration.5

EDUCATIONAL RESOURCES

- TryEngineering.org: The Power of Graphene lesson plan (ages 8-18)

- NISEnet activity: Exploring Properties of Heat Transfer (ages 4-adult)

REFERENCES:

- Lee et al. Smart Contact Lenses with Graphene Coating for Electromagnetic Interference Shielding and Dehydration Protection. ACS Nano, 2017. 11(6), 5318-5324. DOI: 10.1021/acsnano.7b00370

- Blomquist, N. Large-Scale Nanographite Exfoliation for Low-Cost Metal-Free Supercapacitors. Thesis, 2016. DOI: 10.13140/RG.2.2.36561.33126

- Novoselov, K., Geim, et al. Electric Field Effect in Atomically Thin Carbon Films Science, 2004. 306(5696) 666-669. DOI: 10.1126/science.1102896

- Poratta, D. Graphene confirmed as strongest material. Columbia Engineering website, 2008: http://engineering.columbia.edu/graphene-confirmed-strongest-material

- Choi & Park. Smart Reinvention of the Contact Lens with Graphene. ACS Nano 2017. 11(6), 5223-5226 DOI: 10.1021/acsnano.7b03180