Did you know that when you walk through an art museum, there is a good chance that you will come across nanoparticles? Long before nanoparticles began finding applications in battery technology, experimental medicine, and electronics, they were used to color pottery. Pottery gets its characteristic colors and textures from mixtures of chemicals called glazes. Glazes are applied to pottery after a firing in a kiln hardens the clay. After glazing, a second trip to the kiln causes a chemical transformation in the glaze that gives the piece of pottery its characteristic colorful finish. People have been developing glazes for centuries, resulting in a large variety of glazes capable of producing many surface colors and effects (Figure 1).

In some cases, nanoparticles are responsible. For example, nanoparticles have played an important role in the development of European ceramics, appearing in ancient Roman times as well as throughout the Middle Ages and Renaissance. While studying Renaissance ceramics, researchers identified the presence of gold, silver, and copper nanoparticles, all of which contribute to the pottery’s color and luster (Figure 2). For example, copper nanoparticles create a red finish, while amber-colored pottery is the result of silver particles. Meanwhile, the presence of gold and copper nanoparticles make the surface shinier. Even though ceramic artists hundreds of years ago had no idea what a nanoparticle was, they were taking advantage of nanoparticle properties in ways that did not become apparent until recently.1,3

In a finished ceramic, nanoparticles can range from 5 to 10 nm in size and occupy a thin layer on the surface.1 At this size, they are able to produce color through a process called surface plasmon resonance emission, which allows light that hits the nanoparticle to be re-emitted at different wavelengths.2,4

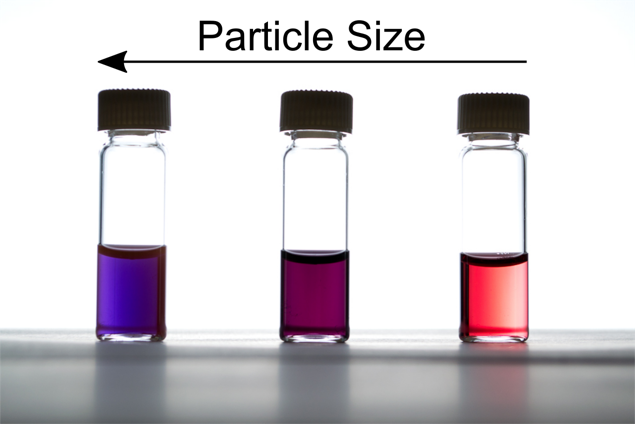

The shape, size, and surface characteristics of a nanoparticle can influence its color properties, as shown in Figure 3.

This year brought renewed interest in replicating these ancient glazes, with researchers at the University of Richmond in Virginia successfully recreating red and gold glazes from the Renaissance. Apart from their historical significance, nanoparticle glazes offer crucial advantages over their contemporary counterparts. Specifically, they require significantly less metal, potentially reducing costs and minimizing the risks of metal exposure. Furthermore, the metals they use, such as gold and silver, are much less toxic than the barium and chromium found in other glazes. Their increased safety and sustainability make nanoparticle glazes an attractive alternative to the glazes that are currently in use.2

Hopefully, this blog post has shown you that nanoparticles have been used to add color to artwork for longer than you may have imagined. Recent scientific research into nanoparticle glazes has revealed the process that creates their color, as well as providing a method to recreate their effects. Today, a better ability to make nanoparticles with different sizes and surfaces can allow modern glaze designers to not only recreate, but also greatly expand upon the palette of glazes used in ancient pottery. Maybe you will even see them on your next trip to the art museum.

EDUCATIONAL RESOURCES

- Education in Chemistry: The Chemistry of Pottery by Stephen Breuer

- Journal of Chemical Education: The Joy of Color in Ceramic Glazes with the Help of Redox Chemistry by Allen Denio

REFERENCES

- Padovani, S.; Sada, C.; Mazzoldi, P.; Brunetti, B.; Borgia, I.; Sgamellotti, A.; Giulivi, A.; D’Acapito, F.; Battaglin, G. Copper in glazes of Renaissance luster pottery: Nanoparticles, ions, and local environment. Journal of Applied Physics, 93, 10058 – 10063, 2003. doi: 10.1063/1.1571965

- Lambertson, R.H.; Lacy, C.A.; Gillespie, S.D.; Leopold, M.C.; Coppage, R.H. Gold nanoparticle colorants as traditional ceramic glaze alternatives. Journal of the American Ceramic Society. 2017; 00:1–9. doi: 10.1111/jace.14928

- Ball, P. Renaissance potters were nanotechnologists. Nature News. 2003. doi: 10.1038/news030623-17

- Malicki, Michal. Gold Nanoparticles – Surface Plasmon Resonance. Clean Energy Wiki.